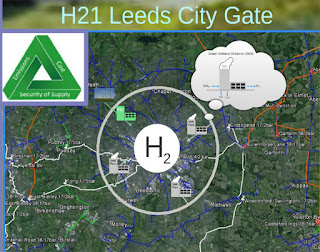

The 'hydrogen city' plan involves building “steam methane reformer” plants

around the city to remove the carbon from methane in the national gas grid.

A £55 million pilot project to convert the

natural gas network in the city of Leeds to take hydrogen gas is being proposed

by the city's gas network provider. The 'hydrogen city' proposal is a leading

example of how some cities and energy supply companies are considering ways to

decarbonise heating and cooking in the future and become less dependent on

fossil fuels. Hydrogen produces only water and heat when burnt and, if made

using renewable fuels, is zero carbon.

Northern Gas Networks is responsible for

maintaining the gas grid infrastructure for 2.7 million homes in the north of

England. In this area, 85% of buildings use gas for heating space and water and

for cooking. The company sees the conversion of this network to take hydrogen

as affordable and possible on an incremental scale. It also sees potential for

using the hydrogen for a vehicle refuelling network and for heating, possibly

using micro-CHP, as part of the UK Government's 'Northern Powerhouse' project.

The plan to make Leeds a “hydrogen city”

would eventually cost about £2 billion and involve converting all domestic gas

boilers and cookers to run on hydrogen. Northern Gas Networks (NGN) has already

received £300,000 funding from energy regulator Ofgem

to develop the idea.

How much it will cost per year in billions of pounds Sterling in 2010 value to

convert and install natural gas and hydrogen residential heat technologies to

achieve an 80% reduction in CO2 emissions in 2050. Each point

represents the average annual investment over a 5-year period. Source

A

report

commissioned by NGN from KPMG consultants says that what's called the H21 Leeds

city Gate hydrogen project would position natural gas as more than a

'transitional fuel' on the UK's pathway to a low carbon economy. Desktop modelling

has shown that the current gas network in the UK and particular in Leeds is

large enough to convert hydrogen, and that because of its unique positioning,

Leeds should be the first city to convert.

“Households in Leeds could potentially cook

and heat their homes using pure hydrogen within 10 – 15 years,” a spokesman for

NGN said. The city would then become a centre of excellence for the hydrogen

economy, it is thought.

The project is now looking to secure £55

million to develop a roadmap to hydrogen consisting of evidence that would back

up the project's viability. The work is seen as split into 16 work packages,

covering over 50 projects. Part of this work will be to determine an overall

strategy for UK wide conversion over time.

Conversion would be a major infrastructural

transformation, and many hydrogen compatible appliances and burners would need

to be installed or converted, and a workforce trained to undertake the process.

Hydrogen and electricity would become the dominant heating fuels by 2050.

The gas grid

The UK benefits from an extensive natural

gas pipeline network that supplies 84% of homes. Worldwide, natural gas

supplies around 20% of residential heat, primarily in OECD countries.

Many of the old (local) low-pressure

distribution iron pipes are having to be replaced by polyethylene, and by 2030

this will be complete and they will be able to take hydrogen.

The (national) high-pressure gas

distribution pipes on the other hand are made of steel, which is unsuitable to

transport hydrogen, so a separate network for taking the hydrogen would have to

be constructed. This has happened before, when the network was converted from

town gas to natural gas over a 10-year period, so it is known to be feasible.

Using hydrogen in the network is just one

idea for its future, rather than decommission it completely, after the use of

natural gas has to be abandoned to meet the constraints of climate change.

Other possible uses are to carry bio-methane from the anaerobic digestion of

organic waste, and hydrogen injection.

A

2013

academic study on the future of the UK gas network determined that from a

cost point of view, hydrogen conversion was the cheapest option, and

recommended that the government adopted a long-term strategy to do so. It

concluded that renewable methane from anaerobic digestion could probably only

ever meet around ten per cent of total gas demand due to the limited

availability of the waste organic matter (food and agricultural waste).

The range of heat appliances in homes in 2050 necessary to achieve an 80%

reduction in CO2 emissions. Source

One of the drivers for the project is the

UK's 2008 Climate Change Act, which requires the government to reduce UK

greenhouse gas emissions in 2050 by 80% relative to 1990 levels.

A major stumbling block for this strategy

is the problem of carbon capture and storage. If the hydrogen is produced by

reforming methane, which is composed of carbon and hydrogen, the hydrogen would

be pumped into the gas grid, but the carbon would need to be stored underground

to prevent it entering the atmosphere. The likeliest place for storing it is

back underneath the North Sea, where the gas came from in the first place.

However, last year the government scrapped

a £1 billion carbon capture and storage pilot project that would test out this

idea, so no one yet knows whether this will work.

The use of hydrogen in the gas grid does

have the backing of the Institution of Gas Engineers and Managers, which has

already

said it will help in developing standards for the construction and testing

of hydrogen gas distribution systems and safety.

The role of hydrogen in decarbonising buildings

A

study published two years ago criticised governments for not considering

the role hydrogen could play in decarbonising buildings and heating. It

concluded that fuel cells can especially offer wider energy system benefits for

high-latitude countries because of their peak electricity demands in winter;

but the same could be true in low latitude countries which have a high electricity

demand for air conditioning.

The study argues that gas networks could

prove difficult to displace with alternatives, particularly because consumers

who have them like their gas boilers, which they perceive as safe, cheap,

effective and easy to control, so why not adapt the existing markets and

infrastructure for gaseous heating fuels and convert these to use hydrogen?

Both of the above academic studies are

co-authored by Paul E. Dodds of University College

London, an expert in energy economics. But the UK government also appears to be

backing the idea, building on a 2012 strategy paper on

The

Future of Heating: A strategic framework for low carbon heat in the UK.

This paper argues that although

constructing a high-pressure national grid for delivering hydrogen to

households could be very costly, as intercity pipes would need to resist

high-pressure hydrogen and corrosion, low-pressure local grids may be a more

viable solution. This will potentially enable them to be connected to other

local means of supplying the gas, for example by the electrolytic splitting of

water using renewable electricity when more of it is being generated than is

required at the time, such as by wind power at night.

A follow-up 2014

White

Paper from the UK Hydrogen and Fuel Cell (H2FC) SUPERGEN Hub examined the

roles and potential benefits of hydrogen and fuel cell technologies for heat

provision in future low-carbon energy systems. It agreed with the idea and

proposed that in the shorter term small amounts of hydrogen be injected into

the gas networks to reduce the emissions intensity of grid gas.

It also criticised government policies on

renewable heat for marginalising hydrogen and fuel cells.

This approach, together with the use of

fuel cell micro-CHP, would reduce the need to depend on heat pumps as the main

solution for decarbonising heating. Heat pumps have recently been criticised

because they either require a lot of space or, in the case of air course heat

pumps, are too noisy.

The options for micro-CHP

Micro-CHP (combined heat and power) is a

boiler that not only heats a building but also generates electricity. It's

around the size of a small fridge or washing machine.

Like their big brother, conventional CHP, it uses

the gas more efficiently, making the boiler 90% efficient.

The current crop of models are based on the

Stirling engine, Organic Rankine Cycle (ORC) or

internal combustion engine.

The first

two have high thermal efficiency and output but low electrical efficiency

(10%), and this is a sticking point.

The cumulative

number of fuel cell micro-CHP systems deployed in three major regions, showing

historic growth (solid lines) and near-term projections (dotted lines). Source.

A

2011

trial by the UK’s Carbon Trust concluded that micro-CHP can cut electricity

bills and overall CO

2 emissions by 15–20% when they’re the lead

boiler in larger contexts like care homes, district schemes, apartment blocks

and leisure centres.

The best application

for them therefore is a medium-to-large, moderately well-insulated building, perhaps

with solid walls, solid floors and no loft space, that is hard to insulate well

and has a relatively large heat demand; or a cluster of buildings.

Micro-CHP offers more limited benefits for

smaller and newer dwellings, however, because they are more energy-efficient or

have too little requirement for heat.

The key to success in micro-CHP is matching

the thermal output to the building’s pattern of use, so that they operate not

intermittently but for many hours at a time, making the value of electricity

generated pay for the marginal investment as quickly as possible. It therefore

works best with a buffer storage tank to save the surplus heat for later. Grid

connection for electricity export is crucial to micro-CHP’s widespread

acceptance.

On average, half of all electricity generated

by a typical 1kWe micro-CHP device is exported to the grid, as it’s not needed

at the time. Reliability is also a key issue; service agreements will be

essential.

Superinsulated

homes will have to wait until the next generation of machines,

based on fuel cells. These generally come in two types – proton exchange

membrane fuel cells (PEMFCs) and solid oxide fuel cells (SOFCs). They have a

heat to power ratio that is approximately equal, so for example they could

produce 5kW of heat and 5kW of electricity.

CO2 savings from fuel cells are therefore

country- and site-specific, depending on the carbon intensity of grid

electricity and on the heating system that is displaced.

At five times the installation cost

of residential gas boilers (around £12,000 for 1 kW residential systems,

but costs are falling 10–15% per year), they're not cheap but are beginning

to compete with other low-carbon heating technologies and their running

costs are lower, even without public policy support.

Hydrogen in the home

The range of heat appliances in homes in 2050 necessary to achieve an 80%

reduction in CO2 emissions, with and without hydrogen conversion. Source

By contrast, could we live with hydrogen?

The physical properties of hydrogen differ from natural gas, so switching to

hydrogen would require changes not only to the gas network but to heating and

cooking appliances.

Gas appliances designed for natural gas

cannot generally be used directly with hydrogen, mainly because the combustion

velocity or flame speed is higher for hydrogen than for natural gas. Conversion

would mean replacing the burner heads. Hydrogen also spontaneously ignites much

more quickly than natural gas, which will necessitate modifications to

spark-ignition gas engines and gas turbines to avoid flashback and knocking.

Hydrogen has a lower calorific value than

natural gas per unit of volume, so a greater volume of gas must be burned for

the same heat level. But this is made up for by the fact that the gas flows

quicker under the same pressure due to its lighter molecules. Hydrogen is also

invisible and odourless, so would need odorants to be added to it to enable

detection for safety reasons.

However, because hydrogen can be burnt

directly in a combi-boiler it requires no additional

space in the home. Hydrogen boilers are also much cheaper than heat pumps. They

could therefore provide zero-carbon heat without much disruption to living

patterns, while being affordable.

Hydrogen may also be used for district heating.

Boilers designed specifically for hydrogen are under development.

Gas heat pumps may also be converted to

hydrogen. These are already commercially available in some countries for

household or commercial use, and have much higher efficiencies than gas

boilers.

The road to a hydrogen city is clearly a

long one that is not without difficulties. However, Northern Gas Networks is

one gas network operator that is not going to give up the value of its assets

easily and is determined to explore the options.

Leeds, a pioneer city of the first

industrial revolution, could yet become a pioneer of the post-carbon

revolution.

David Thorpe is the author of: